VFD Inverters for Plants: How They Work, Core Settings & Energy-Savings Math

A VFD (Variable Frequency Drive) lets your motor run at the speed the process needs—no more, no less. For variable-torque loads like fans and pumps, a small speed reduction can slash power dramatically. That’s why VFDs are often the fastest route to lower energy bills and smoother automation.

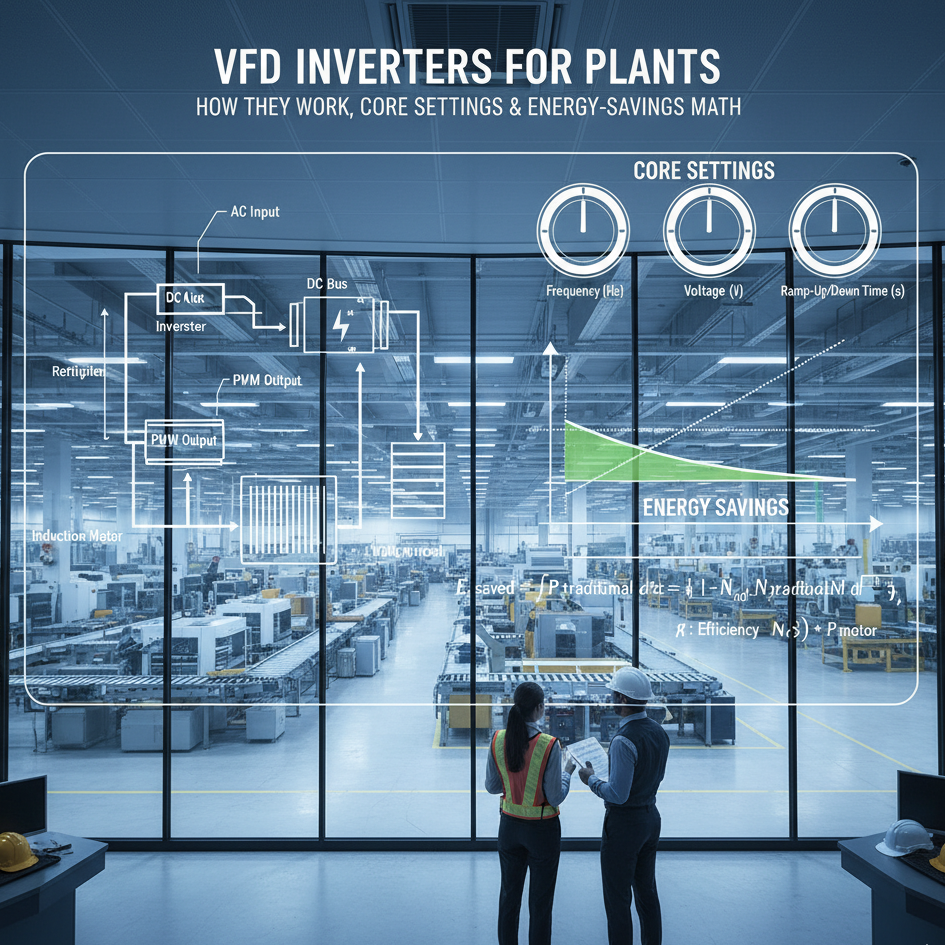

How a VFD Works (In Plain English)

Incoming AC is rectified to DC, then the inverter creates a new AC waveform at the frequency you set. By controlling the V/F ratio, the VFD maintains usable torque even when you slow the motor down.

Core Parameters You Should Set First

- Base frequency & V/F profile – anchors how torque is delivered.

- Acceleration/Deceleration time – avoids water hammer and current spikes.

- Current limit & protections – overcurrent, overvoltage, over-temperature.

- Built-in PID – holds pressure/flow without a separate controller.

- Auto-tuning – adapts drive control to the motor’s real parameters.

Soft Starter vs VFD

- Soft starter: gentler start, but final speed is fixed at line frequency.

- VFD: variable speed all the time—this is where the energy savings come from.

The Easy Energy-Savings Math (Fans/Pumps)

For many fans and pumps, power is roughly proportional to the cube of speed. Cut speed by 20%? Power can drop by about 50% (system-dependent). Add sensors and use the VFD’s PID to deliver on-demand performance instead of “always full.”

Installation & EMC Best Practices

- Use shielded motor cables and proper grounding to limit EMI.

- Consider reactors/harmonic filters if THD is an issue.

- Keep control wiring away from power cables.

- Ensure panel ventilation: drives dissipate heat.

PLC/SCADA Integration & Safety

Network the VFD to your PLC (e.g., Modbus/Profinet) to trend speed, current, and alarms. On the safety side, interlocks and E-stops must be designed correctly—no shortcuts.

Explore next: Products · Branch Network · Contact Us

FAQs

- Will a VFD always save energy? Mostly for variable-torque loads. Evaluate constant-torque cases.

- Do I still need a soft starter? Usually no—VFDs already ramp smoothly.

- What about harmonics? Mitigate with line reactors/filters and good panel design.

- Typical ROI? Depends on run hours and load profile; many projects pay back quickly.

- First-time settings? Start with base frequency, V/F curve, accel/decel, and current protections.